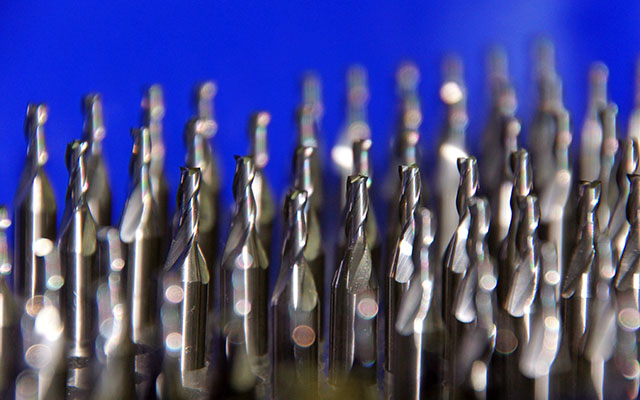

Professional distributor & manufacturer, we provide you machining technology and total solution of products, not only products, but also increasing your competetiveness

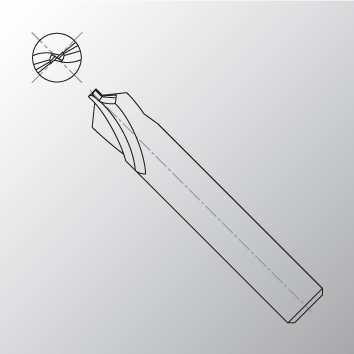

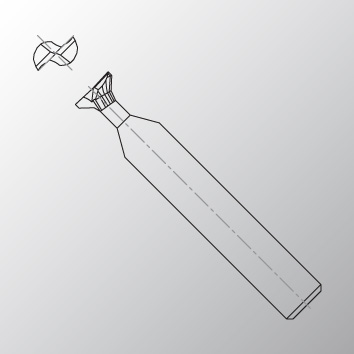

PRODUCTS

CONTACT

- Chou & Hsieh Co., Ltd.

- 2F, No. 82-1, Sec. 1, Guanfu Rd., Sanchong Dist., New Taipei City, 24158, Taiwan

- TEL: 02-85124699

- FAX: 02-85124709

- sales@3dmilling.com.tw